Without a doubt, in metal fabrication, success is indeed if the work consists of top-grade to flawlessly crafted parts that are used in things like skyscrapers or airplanes. The bending press tool that works behind the scenes turns metal sheets into the raw components of perfection when used in the construction of structures like skyscrapers or planes. Your knowledge of this tool, whether you are an experienced professional or an inquisitive beginner, will determine whether you will be successful or not.

In this guide, one will be able to gain an insight into what the bending press tool does differently, how it can be employed such as its various types, and how it is adding new dimensions to the industries with its ability to perform tasks in a never-witnessed manner so far. Let’s devote knowledge to resolution! It’s possible!

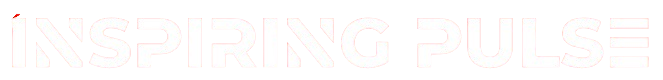

What is a Bending Press Tool?

A bending press tool, which is frequently called a press brake, is a mechanical device that is programmed to bend and shape metal with the topmost accuracy. This press is operated by compressing a crimped metal workpiece to form the end product at an accurate angle or curve. It is not only capable of creating simple 90-degree bends but also of fine geometries depending on the machine’s system configuration and tooling-type.

Types of Bending Press Tools

In the family of bending press tools, there are hand presses for little projects, hydraulic press brakes for heavy tasks, and CNC bending brakes also used for automatic, precise mass production. Every kind of this tool is suitable for a different project.

Manual Bending Press

Manual press tools are the perfect solution for small tasks that are manual and at the same time reasonable. They don’t need extra power to work and are preferred for super-precise and detailed work on thinner parts.

Hydraulic Press Brake

The machine dominates the industrial field, pressing the device with hydraulic power, which provides more pressure. It has a reputation for being indestructible and dealing with thicker metals.

CNC Press Brake

These CNC press brakes perfectly fit the high-tech description as Computer Numerical Control, which are affordable and programmed by the user. They are great for big volumes, as they are simple and intuitive to use, and they are able to make consistent and complicated bends with almost no effort required.

Applications of the Bending Press Tool

One of the most important tools in every sector is the bending press tool. Its versatility is one of the reasons for its greatness, and it is widely used in the fabrication of metal:

- Automotive Industry: Car manufacturers are able to produce their one of a kind chassis components and exhaust systems through the use of this technology which is not only of utmost precision but also of safety and reliable performance.

- Construction: The structural pieces that are used in buildings can be built from it.

- Planes and Spaceships: Effective for design of lightweight, and high-strength parts which can survive the harsh environmental conditions.

- Art and Design: It helps artists and designers to experiment with unique metal forms for installations and furniture.

Also Read: What Does JSP Mean on Snapchat? A Guide to Snapchat Slang

Key Benefits of Using a Bending Press Tool

One of the best things about the bending press tool is that it has no rivals in terms of the highest precision, efficient production, versatility in different materials, and durability for the long-term metal fabrication projects.

Precision and Accuracy

The tool is great for manufacturing with standardized folds and for the creation of detailed figures, the bending press tool is a first-rate item that provides extremely precise work that is exactly according to, or even surpasses, the specified dimensions.

Efficiency

Portable press tools, mainly those that employ computer numerical control (CNC), are amongst the newest technological innovations and have made the production process more efficient, thus helping to reduce the time and labor costs.

Versatility

This tool and different ones too are used with a variety of dies, i.e., it is versatile and can be used with different types of different-banding materials, for example, aluminum, steel, and brass.

Durability

Solid inventory pressing tools are strong and long-lasting, so they bring the customer good return on investment for a longer time.

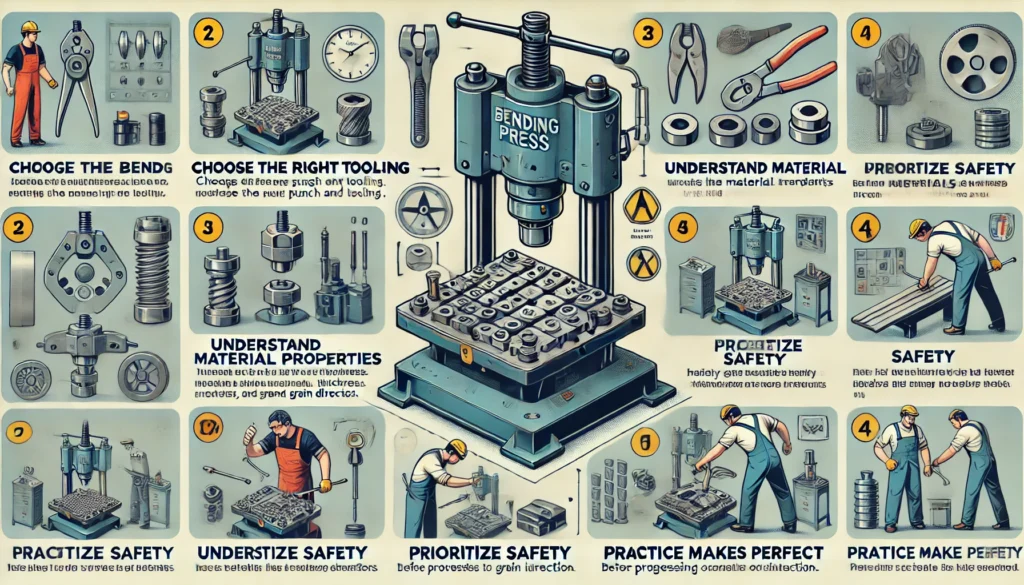

Tips for Using a Bending Press Tool

Tips for using a bending press tool: when using a bending press tool, make sure to choose the right tooling, understand your material’s properties, always prioritize safety, and practice by making simple bends first before creating complex designs.

Choose the Right Tooling

The punch and die set used to produce the bend directly affects the bend’s surface quality. Only select tools that will work best for your engineering designs and make them stand out from the competition.

Understand Material Properties

Materials are not always bendable. Moreover, different metals have varied improper bending features. Bending parts can be affected by various variables such as material thickness, hardness, and the direction of the grain in which metal is formed.

Prioritize Safety

Make sure to always put on the safety gear which should be provided and follow the manufacturer’s instructions to avoid any type of safety accidents.

Practice Makes Perfect

In the case of starters, it is best to start with the easy bends so that you get used first to the machine’s working processes before you start making the harder designs.

Future Trends in Bending Press Tools

Future trends in bending press tools cover smart machines with AI, IoT integration, and sustainable solutions with energy-efficient designs as well as enhanced automation for fully autonomous production lines.

Smart Machines: By mounting sensors that use IoT and AI on them these machines can predict when they need maintenance and adjust bending sequences.

Sustainable Solutions: The energy-efficient models are getting more recognition as they are helping to reduce their carbon footprints.

Enhanced Automation: Factories are using robots and automated systems to move factories away from being partially autonomous to fully autonomous production lines.

Final Thoughts

At the bending press machine zone, it is more than just a piece of equipment. It is a marvel in the art of metal fabrication. It is the only means of producing the pieces for a plane, the very tool of construction in nowhere to be seen skyscrapers, or the masterpiece of art creation. This is the tool, which once mastered, opens up the world of precision and creativity to you.

Want to get better at metalworking? Become a part of the bending press tool world and explore the millions of options they offer you!